Products

Cover Flux

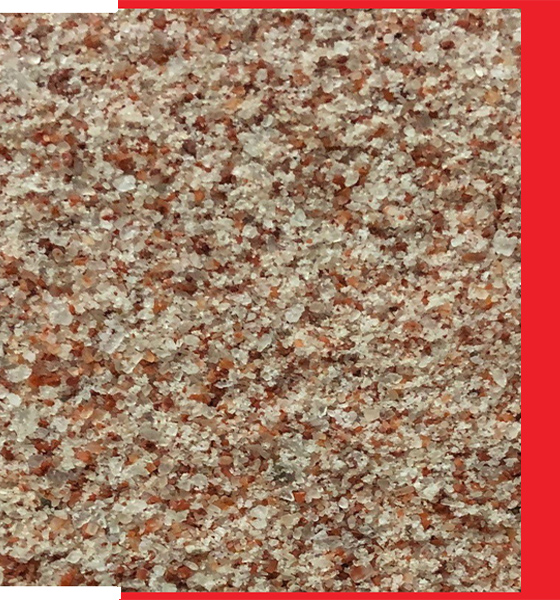

Cover fluxes are applied to the melt surface to form a physical cover and improve metal recovery. AMCOR can trace its roots back to the original development and formulation of cover fluxes for UBC recycling in the 1960s. Today, cover fluxes are used almost anywhere aluminum scrap is melted. Chemistry and particle sizing are critically important in cover fluxes in order to achieve the desired melting point and performance.

Specialty

AMCOR’s expertise is developing and producing high-quality non-ferrous fluxes. Our comprehensive product line includes all purpose, low smoke, fluoride-free and sodium-free exothermic fluxes and refining agents.

A series fluxes for aluminum

AMLOX®, MR and NS fluxes for aluminum alloys

B series fluxes for brass and bronze alloys

Zincor and Z series fluxes for zinc alloys

HOTEX™ ferrous and non-ferrous hot topping compounds

Fluxes are offered in standard packaging listed below, or custom packaging to meet your needs.

- 2,000 lb or 1,000 lb gaylord boxes

- 2,500 lb FIBC tote, super sack

- 500 lb drums

- Individual heat-sealed bags of 5 lb, 10 lb, 20 lb or 25 lb

Tap Cones

Tap cones act as a plug to regulate the flow of molten metal from furnaces and ladles. AMCOR manufactures vacuum-formed tap cones designed to fit the size and shape of the mandrill and the tap hole block. Common sizes are in stock or available to order, while other custom sizes can be designed and produced to a target specification.